OPERATIONS

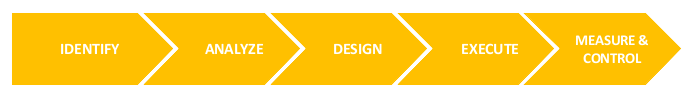

Our operations are based on development plans for hydrocarbon fields begins with the unified reservoir properties based on integrated production analysis by specializing in non-sequential integration of knowledge of the static field model with the dynamic properties of the reservoirs to reduce the uncertainty and the risk associated with different interpretations of them. These results will be the entrance to apply our management indicators, which result in optimizing the planning of exploration and production operations in the field.

Our operations are on the Roanoke field located in the David Jefferson’s Parish in the state of Louisiana, United States.

The strength of our organization allows us to explore for and identify hydrocarbon resources, across all geological and geographical environments, using industry-leading technology and resources. We use our experience, capabilities and understanding of the global hydrocarbon systems to identify and prioritize all quality resources based on a customized Field.

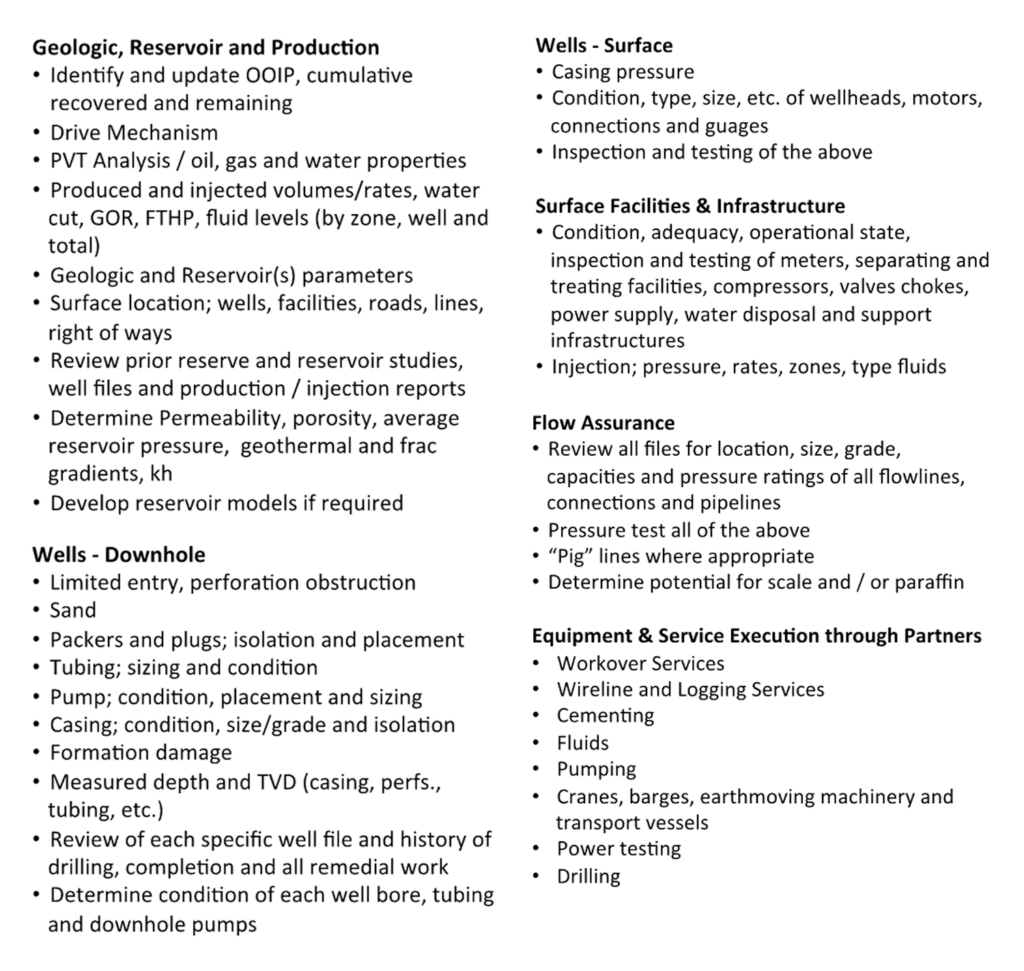

Geologic, Reservoir and Production

- Idenfify and update OOIP, cumulative recovered and remaining

- Drive Mechanism

- PVT Analysis / oil, gas and water properties

- Produced and injected volumes/rates, water cut, GOR, FTHP, fluid levels (by zone, well and total)

- Geologic and Reservoir{s) parameters

- Surface location; wells, facilities, roads, lines, right of \yays

- Review prior reserve and reservoir studies, well files and production / injection reports

- Determine Permeability, porosity, average reservoir pressure, geothermal and frac grad ients, kh

- Develop reservoir models if required

Wells – Downhole

- Limited entry, perforation obstruction

- Sand

- Packers and plugs; isolation and placement

- Tubing; sizing and condition

- Pump; condition, placement and sizing

- Casing: condition, size/grade and isolation

- Formation damage

- Measu red depth and TVD (casing, , tubing, etc.)

- Review of cash specific well hIe and history of dr illing, completion and all remed ial work

- Determine condifion of each well bore, tubing and downhole pumps

Wells – Surface

- Casing pressure

- Condifion, type, size, of wellheads, motors, connections and guages

- Inspection and tesrin8 of the above

Surface FacilitiesB Infrastructure

- Condifion, adequ acy, operafional state, inspect on and test ng of meters, separating and treading facilities, compressors, valves chokes, power supply, water disposal and support infrastructures

- Injection; pressure, rates, zones, type fluids

Flow Assurance

- keview all files for location, size, grade, capacities and pressu re ratings of all flowlines, connections and pipelines

- Pressure test all of the above

- Pig lincs where appropriate

- Determine potential for scale and / or paraffin

Equipanent & Service Execution through Partners

- Workover Services

- Wireline and Logging Services

- Cemening

- FIuids

- Pumping

- Cranes, barges, earth rnovi ng machinery and

- Power testing

- Drillind

Sustainability

Committed To Keep People Healthy & Safe

We Follow Best Practices

- Sustainablility

- Project On Time

- Modern Technology

- Latest Designs